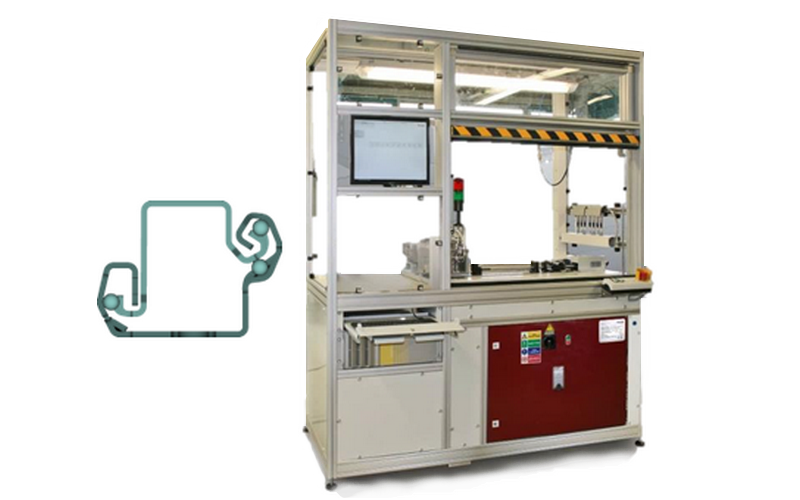

3D measurement concept:

- Measuring head with pneumatic sensors moves down the rail and measures at defined measuring positions

- Cross-section profile is measured independently from the shape deviation (straightness) of the rail longitudinal axis, while simultaneously the magnitude of this shape deviation is identified

Properties:

- Special design adapted to rail geometry

- Variable rail length

- Spot checking

- OK / NOK indication with light signal and on the monitor

- Documentation and archiving of the measurement results including trend evaluation (control chart)

Highlights:

- Division of the rail into segment sections to which freely parameterisable measuring tasks can be assigned

Optional:

- Automated equipment by means of robot handling

- Additional device: Gauge for attachment holes

- Simple version: Small table-top device for measuring the profile outer contour only