Highlights

- Variety of different workpiece types, materials, material thicknesses

- Minimum set-up time

- Short cycle times due to robotic handling, even for extremely varying rivet positions

- High riveting process reliability due to force displacement measuring system

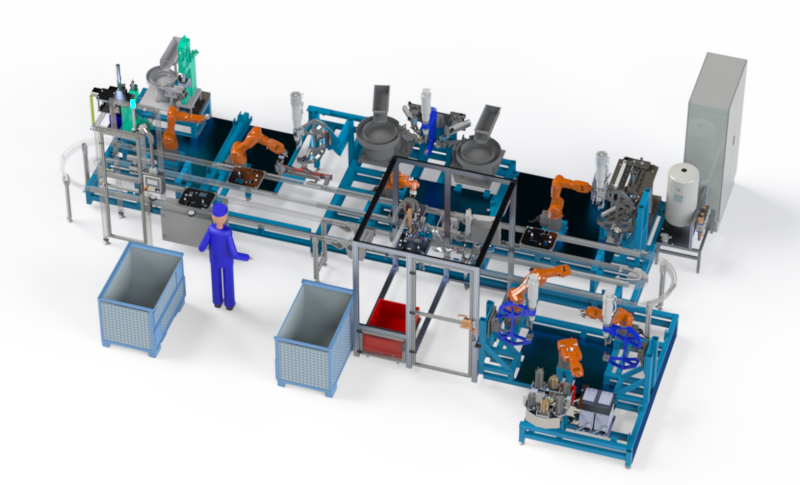

Setup

- Several stations can be coupled for different joining processes

- Robot-guided workpiece adapters

- Parts transport via transfer belt

- Parts supply via conveyors with hopper

- Stationary punch riveting system for different rivet types

- Automatic separation of OK and NOK parts

- Manual equipment of the blank and removal of the finished part